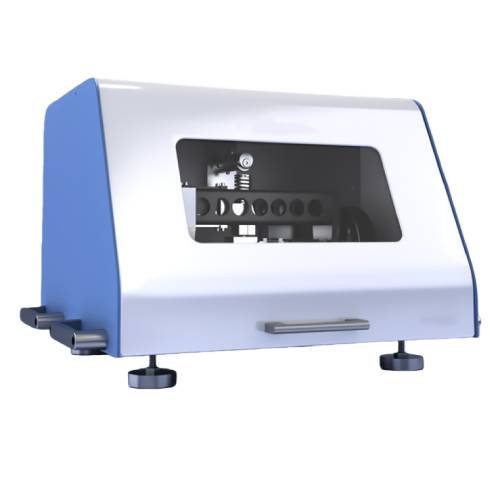

Battery combustion tester

The Battery Combustion Tester is designed for safety evaluation of lithium-ion batteries by simulating direct exposure to flame jet combustion under extreme conditions.

The equipment verifies battery behavior when subjected to sustained flame impingement, including risks of ignition, explosion, rupture, or excessive temperature rise.

The system adopts liquefied petroleum gas (LPG) as fuel with a Bunsen burner configuration and integrates a reinforced explosion-proof test chamber, gas leakage protection, and automatic flame control, making it suitable for laboratory certification testing and safety compliance evaluation.

Application

(1) Cylindrical lithium-ion cells (e.g. 18650, 21700)

(2) Prismatic lithium-ion batteries

(3) Pouch (polymer) lithium batteries

(4) Button and coin cells

(5) Lithium-ion battery packs for consumer electronics

(6) Power batteries for electric vehicles

(7) Energy storage battery modules

Standards

(1) UN 38.3 – Lithium Batteries Transport Testing

(2) UL 1642:2012 – Lithium Batteries Safety Standard

(3) UL 2054:2012 – Household and Commercial Batteries

(4) IEC 62281:2004 – Safety of Primary and Secondary Lithium Cells and Batteries

(5) GB 31241-2014 – Safety Requirements for Lithium-Ion Cells and Batteries

(6) SJ/T 11170-1998 – Lithium-Ion Battery Safety Test Methods

Features

(1) Designed for battery flame jet combustion testing in accordance with GB 31241 and related standards

(2) Uses high-purity liquefied petroleum gas as fuel with Bunsen burner structure

(3) Automatic ignition system with adjustable flame application time

(4) Continuously adjustable flame height to meet different standard requirements

(5) Strictly designed test steel mesh and aluminum mesh in accordance with standard specifications

(6) Precisely defined burner position and test platform geometry

(7) Double-layer reinforced test chamber with explosion-proof pressure relief port

(8) Built-in lighting system for clear observation during testing

(9) Dual gas leakage alarm system with automatic gas shut-off function

(10) High-quality electrical components ensuring stable and reliable operation

(11) Supports switching between local and remote control operation

(12) Optional fire extinguishing module and video monitoring system

Technical Parameters

| Parameter | Specification |

|---|---|

| Test Item | Flame Jet Combustion Test |

| Test Objects | Button, cylindrical, pouch, prismatic lithium batteries |

| Combustion Gas | High-purity liquefied petroleum gas (LPG) |

| Burner Type | Bunsen burner |

| Burner Tube Inner Diameter | 9.5 mm |

| Burner Tube Length | 100 mm |

| Flame Control | Automatic ignition; flame application time and combustion duration 0–999 s, continuously adjustable |

| Flame Height | 10–75 ±2 mm |

| Test Steel Mesh | Wire diameter 0.45 mm, 20 mesh |

| Test Aluminum Mesh | Wire diameter 0.25 mm, 16 mesh |

| Power Supply | Single-phase 220 VAC ±10% (110 VAC optional), 50/60 Hz |

| Rated Power | 0.5 kW |

| Operating Temperature | 25 ± 3 ℃ (recommended) |

| Operating Humidity | 30–90 %RH |

| Explosion Protection | Pressure relief port, reinforced enclosure |

| Auxiliary Functions | Built-in lighting, optional fire extinguisher, optional video monitoring* |

| Installation Dimensions | W1020 × D980 × H1865 mm |

| Equipment Weight | Approx. 357 kg |

* Video monitoring requires customer-provided PoE switch compliant with IEEE 802.3af/at.

Leave Message Get Price