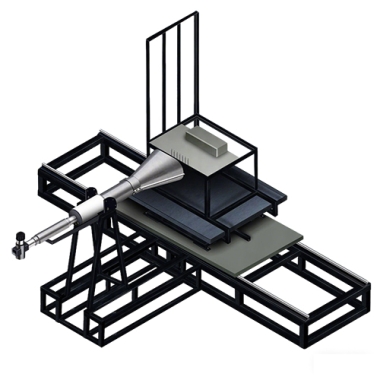

Whole Shoe Flexing Tester(4 Stations)

The QINSUN Whole Shoe Flexing Tester is designed to evaluate the bending and flexing resistance of complete shoes and soles. By simulating repeated flexing under cyclic tensile stress, the tester identifies potential material fatigue, delamination, cracking, or fracture in the upper, outsole, or foxing. It is widely used in footwear R&D, quality control, and compliance testing, ensuring durability and performance of sports, casual, and work shoes. The instrument conforms to major national and industry standards, offering precise, automated, and safe testing.

Application

Used for assessing the flexing durability and crack formation of footwear, including sports shoes, casual shoes, work shoes, and various types of shoe soles. The instrument’s multi-station design allows simultaneous testing of multiple shoes, improving lab efficiency while maintaining high accuracy.

Standards

GB/T 15107, GB/T 22756, GB/T 19706

QB/T 1002, QB/T 2955, QB/T 2977, QB/T 2880

GB/T 3903.1-2008

HG/T 2871-2022 (Method A)

Features

(1) Durable machine body with Dupont powder coating, electrostatically sprayed and cured at 200°C.

(2) Corrosion-resistant aluminum and stainless steel mechanical components.

(3) 16.77 million-color true-color touchscreen for intuitive operation.

(4) Precision variable-frequency motor ensures smooth and low-noise rotation.

(5) Fully automatic one-button testing for user convenience.

(6) High-precision bearings for stable rotation and long service life.

(7) Safety protection: automatic stop when the cover is opened.

(8) Vertical 4-station design allows simultaneous testing and high efficiency.

(9) Adjustable front/rear clamps and screw-locking design secure various shoe sizes.

(10) Movable heel fixture and adjustable speed/angle for flexible testing parameters.

Technical Specifications

| Parameter | Specification |

|---|---|

| Specimen | One pair of shoes simultaneously (4 pieces) |

| Flexing Angle | 0–60° (standard test angle 50° ± 1°) |

| Speed | 5–300 cpm adjustable |

| Control System | PLC + LCD touchscreen |

| Counter | 0–999,999 |

| Weight | 214 kg |

| Power Supply | 1∮ AC 220V, 3A |

| Dimensions | 970 × 750 × 1150 mm |

Accessories

(1) Adjustable clamps and screws for shoe fixation

(2) Movable heel fixtures for different shoe sizes

Operation & Maintenance

(1) Secure the shoe using the front and rear clamps.

(2) Set the flexing angle and speed according to test requirements.

(3) Start the test via the touchscreen one-button operation.

(4) Monitor the process and check for automatic stop if the cover is opened.

(5) Record the number of flex cycles using the built-in counter.

(6) After testing, remove the shoes carefully and inspect for delamination or cracks.

(7) Clean the machine regularly and lubricate bearings as needed.

(8) Inspect clamps and moving parts for wear and replace if necessary.

Leave Message Get Price