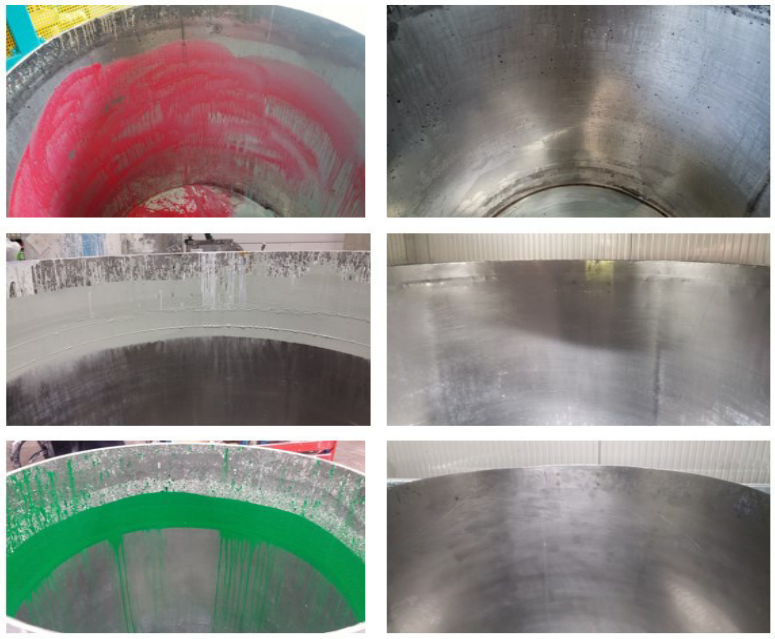

Cylinder Automatic Brush Cleaning Machine

The fully automatic brush cleaning equipment for the pull cylinder adopts a telescopic cleaning brush and combines solvent spraying to achieve thorough cleaning of the cylinder wall and the bottom of the cylinder. The spindle speed is adjustable and the cleaning depth is adjustable. It is suitable for cleaning the inside of the pull cylinder, automatically adjusting the clamping positioning according to the size of the cylinder body, and is compatible with cylinder bodies of different specifications with a diameter of 500-1100mm.

Composition:

The fully automatic cleaning equipment for the pull cylinder consists of a fixed outer frame, an electric control host, an operation panel, a lifting device, a sealing upper cover, a cleaning spindle, an automatic positioning clamping device for the cylinder body, an openable and closable protective net, a three-dimensional cleaning head, a cleaning brush, etc.

Stainless Steel Industrial Cylinder Brush Cleaning Equipment (Also Known as Cylinder Brush Cleaner):

This specialized system is designed for cleaning three-dimensional mixing tanks, mobile cylinders, transfer cylinders, and circulation cylinders. The fully automated process integrates electrically controlled pumps, valves, and hydraulic mechanisms with rotating copper brushes and solvent spray systems. The triple-action mechanism achieves 360° no-blind-spot cleaning through cyclic rotation, combining mechanical scrubbing with chemical solvent action. Operator supervision is required for process monitoring and safety assurance during operation.

Cleaning Process Workflow

1. Simultaneous brush rotation and solvent spray cleaning

2. Solvent collection from cylinder bottom valve into filtration trough

3. Solvent recycling through diaphragm pump to storage tank

4. Magnetic pump repressurization for closed-loop cleaning cycle

5. Multi-stage filtration ensures solvent purity throughout the process

System Configuration

Three-dimensional high-pressure water pump (20-500 kg/cm²)

2. Copper brush cleaning with solvent spray nozzles

3. Tilted discharge structure for residue removal

4. Blowdown port cleaning assembly

5. ATEX-certified explosion-proof components

6. Hydraulic automatic lifting mechanism

7. Fixed external frame with safety guardrails

Leave Message Get Price