Dynamic Shoe Waterproof Bending Tester

Product Introduction:

It is used to test the dynamic waterproof performance of various finished shoes, and the number of times when no water enters the finished shoes or the size of the water penetration area of the finished shoes after completing the specified number of twists and turns to evaluate the waterproof and permeability resistance of the finished shoes under the tortuous condition.

Test principle:

The finished shoe is installed on the finished shoe waterproof resistance zigzag test machine, driving the zigzag part of the tested finished shoe to the zigzag Angle matching the shoe type and the fixed rate of the zigzag machine in the sink equipped with a certain water depth and the water is dyed repeatedly zigzag until the finished shoe water or reach the pre-set zigzag number.

According to the criteria:

GB/T-16641, SATRA TM77

Product Advantages:

The Dynamic Shoe Waterproof Bending Tester offers several key advantages for assessing footwear waterproofness:

Realistic Simulation: Accurately replicates the bending and flexing action of a foot during walking in wet conditions, providing more relevant results than static immersion tests.

Objective Measurement: Provides quantitative data on water penetration resistance (cycles to leakage), reducing subjective evaluation.

Identifies Failure Points: Helps pinpoint exactly where and when water penetration occurs under dynamic stress.

Automated Testing: Allows for unattended testing for a set number of cycles or until leakage is detected.

Repeatable and Controlled: Provides a standardized and controlled environment for consistent testing.

Evaluates Whole Shoe Performance: Many testers are designed to test the complete shoe, assessing the interaction of all components.

Product Features:

A typical Dynamic Shoe Waterproof Bending Tester designed for evaluating footwear waterproofness includes the following features:

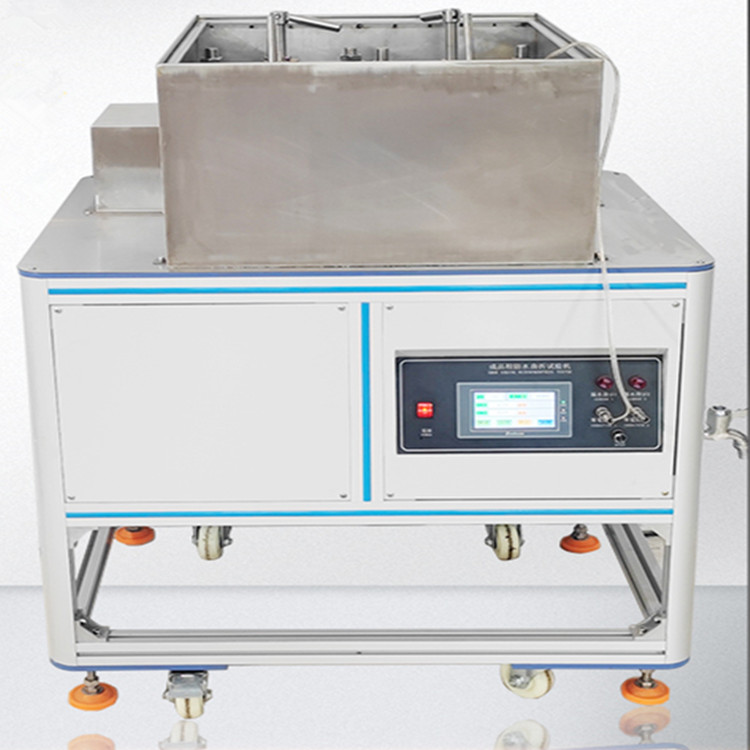

One or more test stations, each capable of holding a complete shoe or material sample.

A dynamic bending or flexing mechanism that simulates the forefoot bending action during walking, with adjustable bending angle and speed/frequency.

A water tank or bath where the shoe or sample is immersed to a specified depth during flexing.

An automatic cycle counter to record the number of flexes.

A leakage detection system, commonly using an electrical conductivity sensor placed inside the shoe or in contact with the back of the material sample, which triggers an alarm and stops the test upon water penetration.

A system for securely mounting the shoe or material sample, often using artificial feet or lasts for whole shoe testing.

Control panel, often a digital display or touch screen, for setting test parameters, monitoring progress, and viewing results.

Corrosion-resistant construction materials due to the presence of water.

Main parameters:

Zigzag Angle: 5—— 60 degrees adjustable

Zigzag speed: 5—— 150 times/min adjustable

Test quantity: 2 finished shoes can be tested at the same time

Count: 0-999999(touch screen display, can be arbitrarily set)

Volume: 73*82* 108CM

Power supply: AC220V, 10A

Leave Message Get Price